The Energy sector is not only an important part of a nation’s infrastructure, but also key to strengthen long-term industry investments. Offshore wind power is essential to the overall energy picture, because it offers several advantages – it does not compete for limited land space, and it accesses the more abundant wind resources that prevail at sea. This is why Offshore Wind is such an important source of energy today and is one of the fastest growing energy solutions globally.

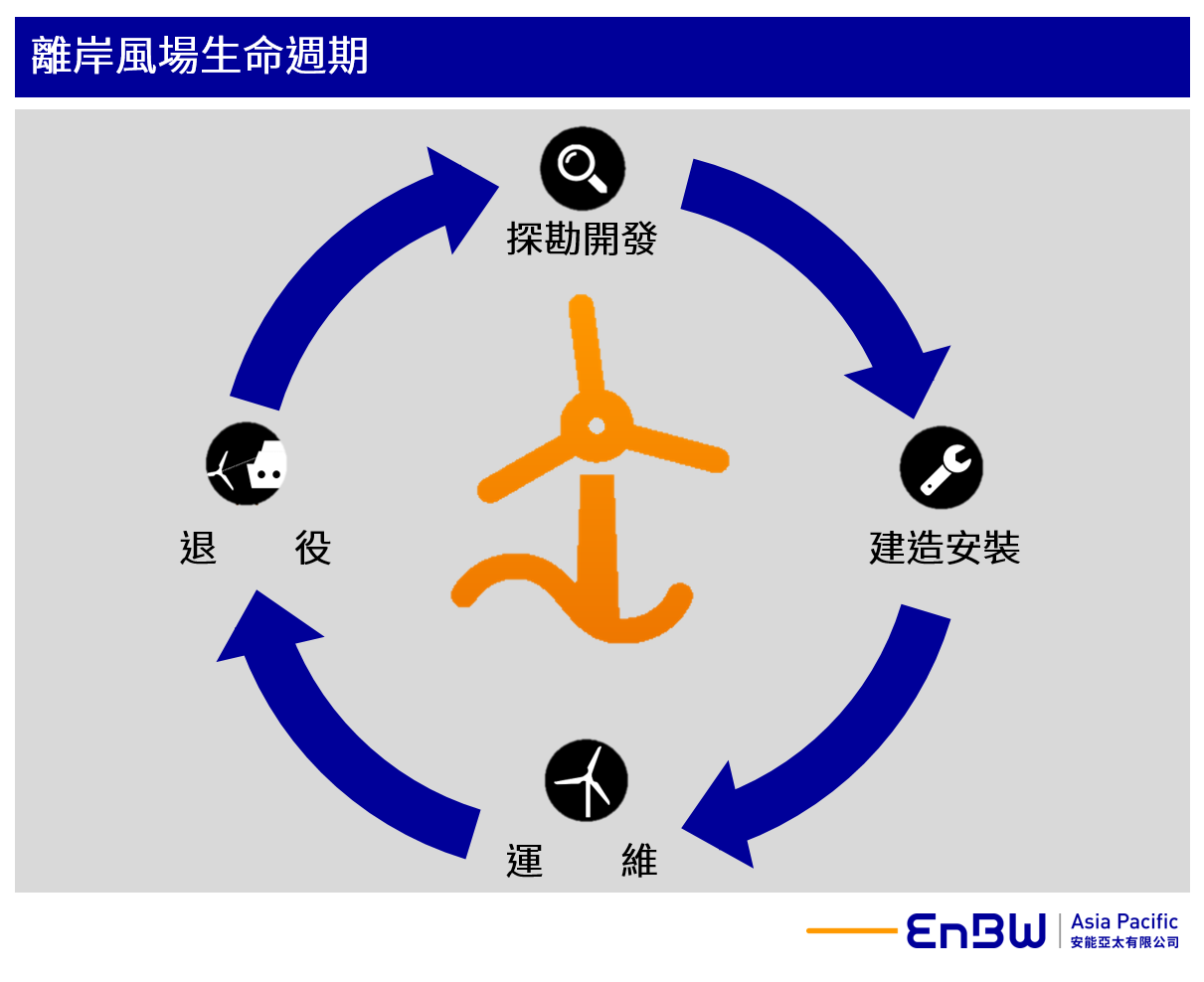

The lifespan of an offshore wind farm (OWF) can be as long as 25 to 30 years and typically goes through four cycles: “Development & Planning” during which the OWF is planned and preparations are made, “Construction” during which the equipment is installed, “Operation & Maintenance” where energy is generated, and “Decommissioning” during which the OWF is built back or undergoes repowering, which means that the older Wind Turbine Generators are replaced with newer ones.

The life cycle of an offshore wind farm includes: development & planning, construction, operation & maintenance, and decommissioning. (Source: EnBW)

Development & Planning – preparation before offshore wind farm construction

OWFs are large-scale infrastructure investments. For developers every offshore wind farm represents an enormous investment. Performing diligent investigations is paramount. This not only helps the developer to identify optimal sites and to make the best possible construction plans, but also enables better anticipation of possible challenges during the construction stage. Furthermore, a detailed investigation report supported by third-party certification provides greater assurance to lenders and investors.

Development & planning typically takes one to five years, and the investigation generally evaluates two crucial aspects: “offshore wind farm potential” and “development impact.” The former involves such research as wind power potential studies and offshore construction surveys, whereas the latter focuses on reducing possible impacts from construction on the ecosystem.

Planning and investigation are critical prior to the construction of an offshore wind farm and must be carried out with the utmost diligence. (Source: EnBW)

Energy Yield Assessment – finding potential sites and the best form of deployment

An offshore wind farm can have a capacity of anything from tens to hundreds of megawatts. A miscalculation of the energy yield or wind power potential may cause an offshore wind farm to perform below its expected capacity and lead to less power production and thus economic losses. For this reason, wind power surveys serve as a very important reference for site selection.

In a wind power assessment, researchers analyze climate observations and perform simulations to determine average wind speed and climate characteristics at the potential site. Based on these findings, researchers can estimate the location’s potential economic benefits. Due to frequent occurrences of typhoons during summer, estimation of extreme wind speeds becomes critical for offshore wind farm projects in Taiwan. With historical wind speed data gathered from previous typhoons in Taiwan, developers is able to estimate extreme wind speeds for the last 50 years using WAsP, a wind speed evaluation software package developed by the Technical University of Denmark. By establishing a guideline on extreme wind speeds, developers are able to determine the required level of wind resistance for a specific location where wind turbines are to be installed.

According to analyses performed by NASA, coastal areas off Changhua in western Taiwan are characterized by average wind speeds of more than 7m/s and average wind power density of more than 750W/m2 all year long. [Note 1]. According to the “Global Offshore Wind Speeds Ranking” published by international consultancy company 4C Offshore, 16 of the world’s 20 most ideal wind sites are located in the Taiwan Strait [Note 2]. Inarguably, Taiwan’s offshore wind power development has significant potential.

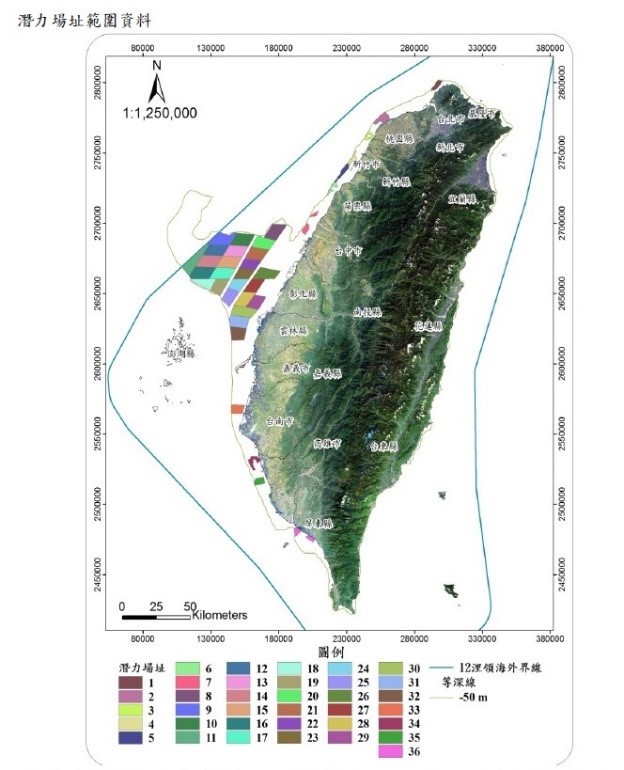

For the first large-scale OWF developments in Taiwan, the Bureau of Energy analyzed the offshore environment around Taiwan and identified 36 potential sites for offshore wind farm development and in 2016 made them available to interested parties. (Source: Ministry of Economic Affairs)

Offshore Geological Survey – studying the environment under water

Geological uncertainty is one of the most significant cost variation factors in offshore wind farm construction. To ensure that all offshore wind farm equipment can be installed onto the seabed in a secure and structurally safe manner, researchers must do a geological survey of the offshore wind farm site before any construction begins, studying its geological characteristics, the underwater terrain, the possible existence of archaeological artifacts, and risks of soil liquification. The survey findings also enable developers to make more comprehensive plans about the construction method, turbine position, and subsea cable layout.

Environmental Impact Assessment – measuring the effects on nature

In addition to conducting detailed survey of the underwater conditions, it is also necessary to assess impacts to the surrounding environment during the development & planning stage. Studies in this respect are focused on the marine ecosystem, migration routes of birds, natural life along onshore cables and near onshore substations, fishery resources and fishing routes.

In Taiwan, the Ministry of Economic Affairs has already excluded areas of high environmental sensitivity [Note 3] when publishing its list of 36 potential sites; furthermore, developers are required to submit an “Environmental Impact Assessment Report” and have it reviewed and approved by the Environmental Impact Assessment Review Committee under the Environmental Protection Agency (EPA) in accordance with the Environmental Impact Assessment Act before proceeding with construction activities. For example, the project that EnBW and her partners are developing- Formosa III –passed its environmental impact assessment in February 2018, and is expected to play a prominent role in phase 3 of Taiwan’s offshore wind development program.

In Taiwan, construction of offshore wind farms may commence only after they pass an environmental impact assessment. (Source: EnBW)

To ensure the performance of an offshore wind farm over its 20 to 25-year lifespan, all developers have to commit significant resources and manpower to site surveys and planning before wind turbines can be constructed in the seabed. Meanwhile, the government and research institutes are actively engaging foreign institutions for independent third-party certification, so that the public can be better informed of the risks of offshore wind farm development and respond accordingly. In June 2019, a group of representatives from CR Classification Society, Ship and Ocean Industries R&D Center, and the Taiwan Accreditation Foundation visited EnBW’s offshore wind center in Hamburg, Germany, to learn about Project Certification and other third-party certification.

While Formosa III has yet to obtain grid approval in Taiwan, its survey and planning efforts are gradually approaching completion. Upon completion, the 3 offshore wind farms with a total capacity of 2GW will represent a new milestone in Taiwan’s renewable energy development.

An offshore wind farm consists of wind turbines, array cables (undersea cables), an offshore substation, export cables, and an onshore substation. The wind turbines catch wind at sea and convert its movement into electricity. This electricity is carried through array cables to the offshore substation where it is maximized the voltage and transmitted through export cables and onshore cables to the onshore substation. The onshore substation converts the incoming electricity to be fed into the power grid for distribution to factories and households. All this equipment is essential for electricity to complete its "journey.”

Electricity generated from an offshore wind farm has to go through subsea cables, an offshore substation and an onshore substation before reaching household users. (Source: EnBW)

The "indispensable teammates" of offshore wind turbines

Wind turbines are often regarded as the most critical components in an offshore wind farm (extended reading: Insight into an offshore wind farm: Turbines – powering offshore wind farms.) However, according to the research conducted by Ship and Ocean Industries R&D Center in 2016, wind turbines only accounted for 41% of the total cost of an offshore wind farm [Note 1], compared to 80% of an onshore wind farm. The study shows that components other than wind turbines also play a significant role in an offshore wind farm. Let’s take a closer look at the "teammates" that support offshore wind turbines!

Cost analysis for offshore and onshore wind farms in Europe. (Information Source: Ministry of Economic Affairs)

Offshore substation

The offshore substation is mainly responsible for consolidating electricity generated from offshore wind turbines and converting it to the appropriate voltage, so that electricity can be transmitted through export cables and into the power grid with minimal potential electrical losses. An offshore substation is typically equipped with a step-up converter, data gathering and monitoring system, diesel generator, alarm system, and marine communication system. To withstand the strong winds, water currents, high salt content and corrosive environment at sea, an offshore substation has to be built within an enclosed steel structure, and all metallic components must be treated to resist corrosion. This requirement makes construction and maintenance of offshore substations much more difficult compared to their onshore counterparts.

EnBW's offshore substation at Baltic 2. (Source: EnBW)

Subsea cables and onshore cables

Subsea cables are the artery that connect an offshore wind farm to the power grid on shore. Subsea cables laid between wind turbines are called "array cables," and they connect wind turbines in a series array. Subsea cables used for transmitting electricity from an offshore wind farm to shore are called "export cables"; they connect to onshore cables, which then take over power transmission on land. Compared to onshore wind power, offshore wind power is presented with more uncertain sea conditions and weather, and a greater number of variables including water depth, geological conditions, seabed changes and sea currents need to be taken into account. These technical difficulties are reflected in the higher development costs. Taiwan’s Ship and Ocean Industries R&D Center also reports that installation of subsea cables alone accounts for 13% of the total cost of an offshore wind farm [Note 2], which is even higher than the cost of a substation (5%). This cost breakdown shows just how critical subsea cables are to an offshore wind farm.

EnBW laying array cables in its offshore wind farm. (Source: EnBW)

Onshore substation

The onshore substation is the part of an offshore wind farm responsible for distributing electricity into the power system on land. Its main task is to adjust electricity to the appropriate voltage before joining the power grid to meet the needs of different users. In Taiwan, for example, electricity generated from offshore wind farms is stepped down to 22-11 kV at a primary substation to supply small and medium industrial users, or it is stepped down at a distribution substation or secondary substation for domestic use [Note 3].

Electricity generated from an offshore wind farm, once stepped down, can be connected to the power grid and distributed to users. (Source: EnBW)

New opportunities from an emerging industry

Every equipment used in offshore wind power involves intricate technologies and requires the support of a strong supply chain. To succeed, the industry requires talents from a wide variety of disciplines, including marine engineering, electrical engineering, project management, and offshore wind farm operations & maintenance.

Scheduled for completion in the end of 2019, EnBW's Hohe See and Albatros projects (currently the largest offshore wind farm project in Germany) provide the best examples of how talents are coordinated to achieve remarkable feats. Since construction activities began in 2017, more than 600 employees have worked on the two wind farms at sea, and more experts from other fields are gathered at EnBW's offshore wind power headquarters in Hamburg, Germany, to provide support for offshore construction.

In fact, according to the survey conducted by the Ministry of Economic Affairs Industrial Development Bureau, Taiwan's offshore wind power industry is expected to have additional demands for 2,010 to 2,700 talents by 2020 [Note 4]. As localized production becomes a reality in 2020, a local offshore wind power supply chain will start to take shape, offering more job opportunities and making Taiwan a competitive player for the emerging industry!

More than 600 employees have worked on EnBW's Hohe See and Albatros projects located in the North Sea. (Source: EnBW)